A HANDS ON STUDENT PROJECT

Under the umbrella of MAKE Projects in the EPFL, the EPFL Racing Team is among the biggest scale projects made on campus. For the members of the team, Formula Student is an excellent way to put into practice everything learned in theoretical courses during the many semesters of their university careers. These students are either designing systems from scratch or improving systems tested on previous cars. From software to hardware, each part is made to perform best on track. These single seaters being composed of numerous complex interconnected systems, this project is highly interdisciplinary and brings students from many engineering specialties together. By the end of their experience as part of the EPFL Racing Team, every member gains key practical and theoretical skills through building the engineering marvels that these race cars are!

FACT SHEET OF ORION

FRAME CONSTRUCTION Tubular space frame

MATERIAL E235 steel Tubing (round 25mm diameter and square 25x25mm)

OVERALL (L / W / H) 3002mm / 1432mm / 1200mm

WHEELBASE / TRACK (Front / Rear) 1570mm / 1250mm / 1250mm

WEIGHT WITH 68kg DRIVER (Front / Rear) 150kg / 196kg

SUSPENSION Double unequal length A-Arm. Push rod actuated horizontally oriented spring and damper

TYRES (Front / Rear) Avon 7.2/20.0-13 / Avon 7.2/20.0-13

WHEELS (Front / Rear) 7×13, 22mm offset, Al Rim, 4 stud bolt / 7×13, 22mm offset, Al Rim, 4 stud bolt

NUMBER OF MOTORS / LOCATION / MAX POWER 1 / Rear / 100KW

MOTOR TYPE Emrax 228

MAX MOTOR RPM 6000

MOTOR CONTROLLER Unitek Bamocar D3 700

MAX SYSTEM VOLTAGE 600V

ELECTRODE MATERIALS LiPo

COMBINED ACCUMULATOR CAPACITY 8.65 kWh

TRANSMISSION RATIO (PRIMARY / SECONDARY) 1 / 4,03

DRIVE TYPE 520 & 530 X-ring chain

DIFFERENTIAL Adjustable clutch pack limited slip diffe- rential

COOLING Single radiator, with fan on main-hoop bracing

BRAKE SYSTEM 4-Disk system, self made 220mm rotors,adjustable brake balance, AP racing callipers

ELECTRONICS Traction control, launch control, self developed BMS

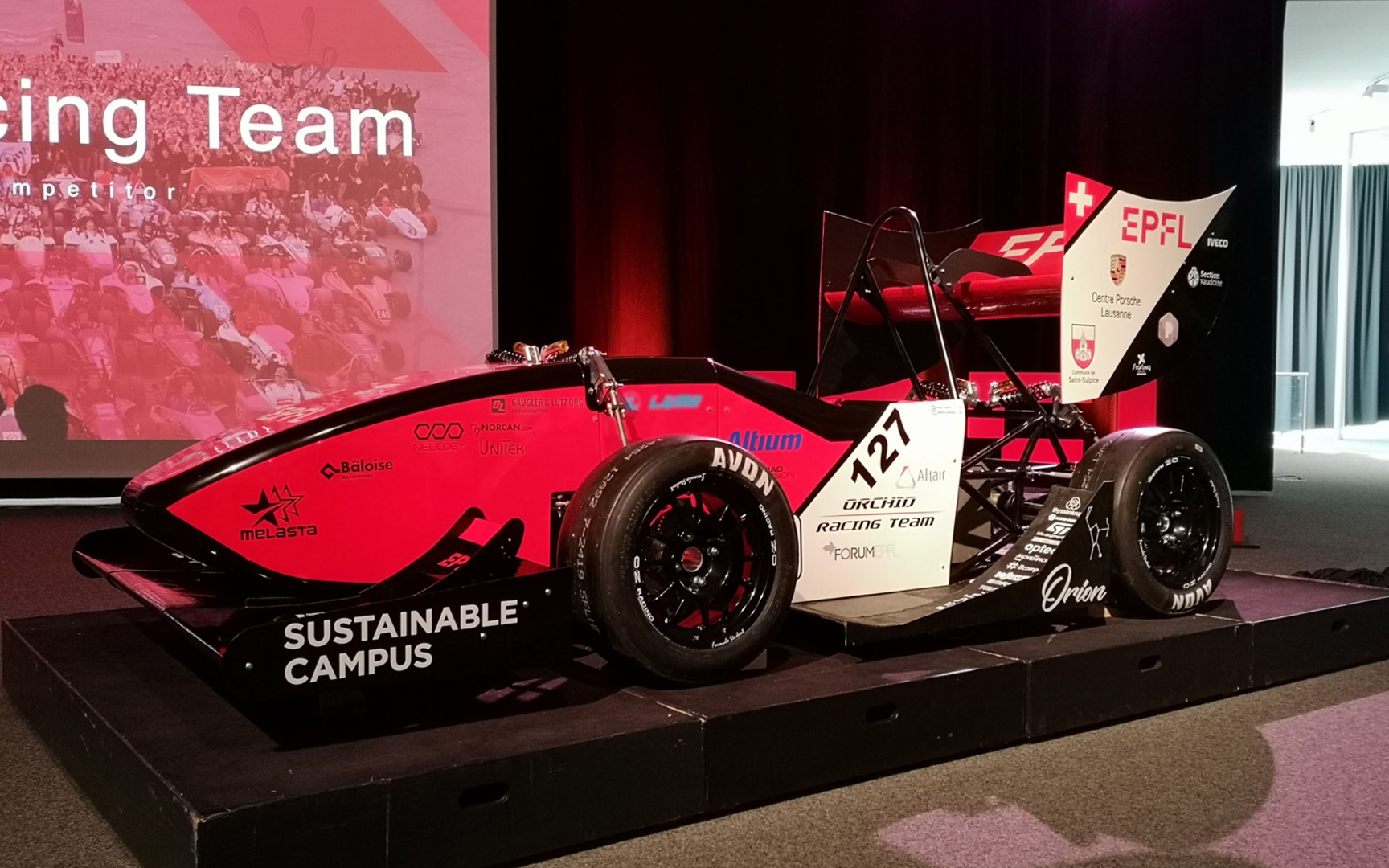

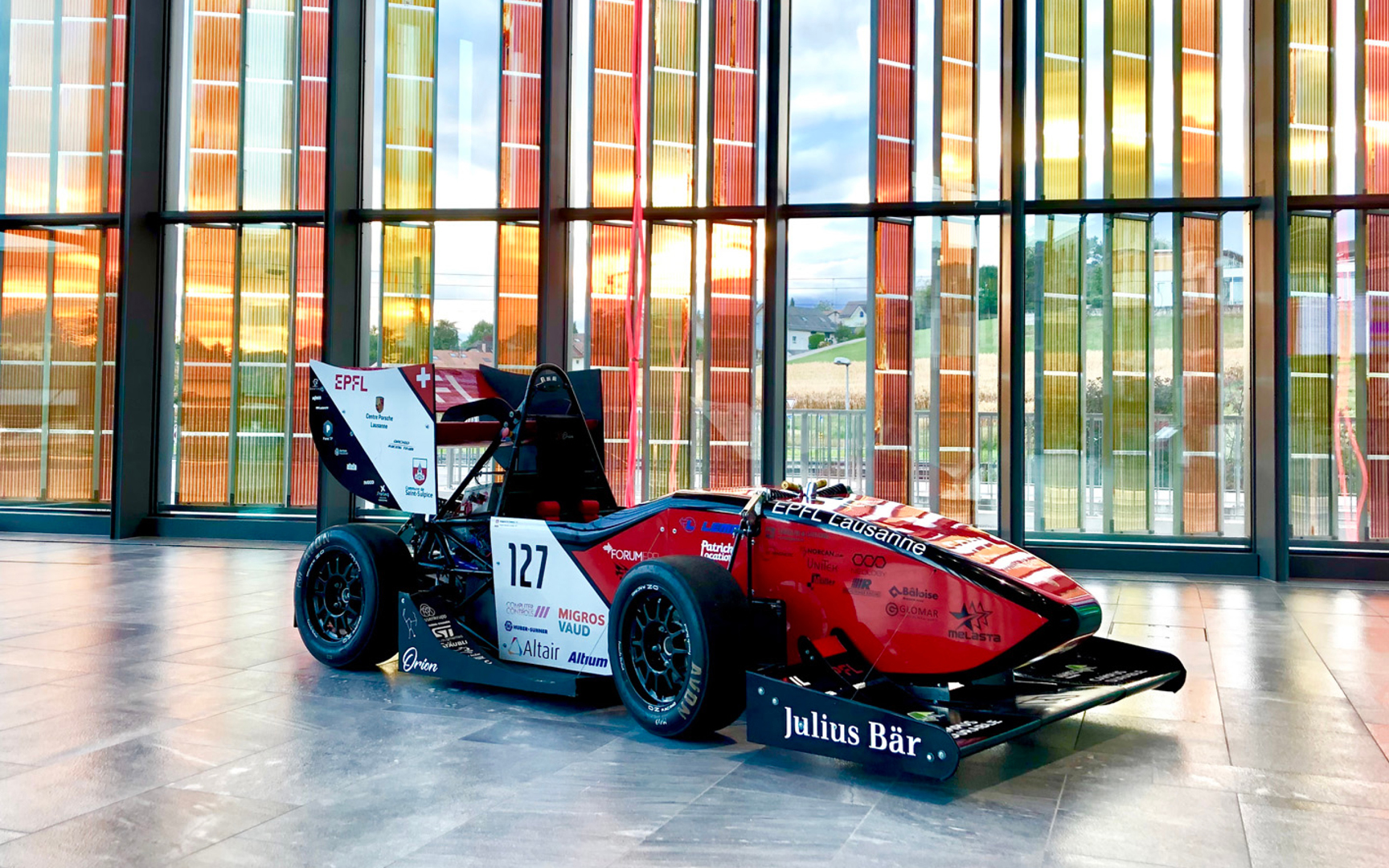

Orion

The team first competed in 2019 with our car: Orion. At this point, the rookie team was formed of around fifty students. This first car was a major challenge, it had to be reliable : reducing the risk of electrical or mechanical failure. If this was achieved, the experiment of building a car for the first time would open the doors for future vehicles and competitions! The team completed a functioning and sturdy car with a complete aero kit, although the car was lacking in electronics, with in-house AMS and safety circuits that were not on point. We went to FS Spain in Barcelona and FS Germany in Hockenheim, although without much success. The most important thing was that the team had learned the true undertaking that making a Formula Student Car is. Additionally, we learned a vast understanding of the teamwork such projects require, as well as how to collaborate to tightly integrate all components of the car and the business.

FACT SHEET OF MERCURY

FRAME CONSTRUCTION Tubular space frame

MATERIAL Steel, 32kg

OVERALL (L / W / H) 3065mm / 1540mm / 1185mm

WHEELBASE / TRACK (Front / Rear) 1570mm / 1240mm / 1200mm

WEIGHT 223.5kg

SUSPENSION (Front / Rear) Double A-arms carbon suspension, pullrod / pushrod

TYRES Hoosier 43075 R25B 16.0 x 7.5-10

WHEELS (Front / Rear) 10” OZ magnesium rims with centerlock

NUMBER OF MOTORS / LOCATION / MAX POWER 2 / Rear / 52KW each

MOTOR TYPE Emrax 188

MAX MOTOR RPM 6500 rpm

MOTOR CONTROLLER Unitek Bamocar D3 400

MAX SYSTEM VOLTAGE 403V

ELECTRODE MATERIALS LiPo

COMBINED ACCUMULATOR CAPACITY 8.3 kWh

TRANSMISSION RATIO (PRIMARY / SECONDARY) 1 / 4,5

DRIVE TYPE Single stage planetary gearbox

DIFFERENTIAL Electronic differential with torque vectoring

COOLING Water cooled

BRAKE SYSTEM regen, adjustable brake balance, 175 mm self made floating discs

DOn’t forget to stay tuned!

We regularly update our social media. You will never miss an event!

How can you become our partner

Send us an email at epfl-racing-team@epfl.ch or call us at +41 77 489 99 07.

For further information click here.